Details

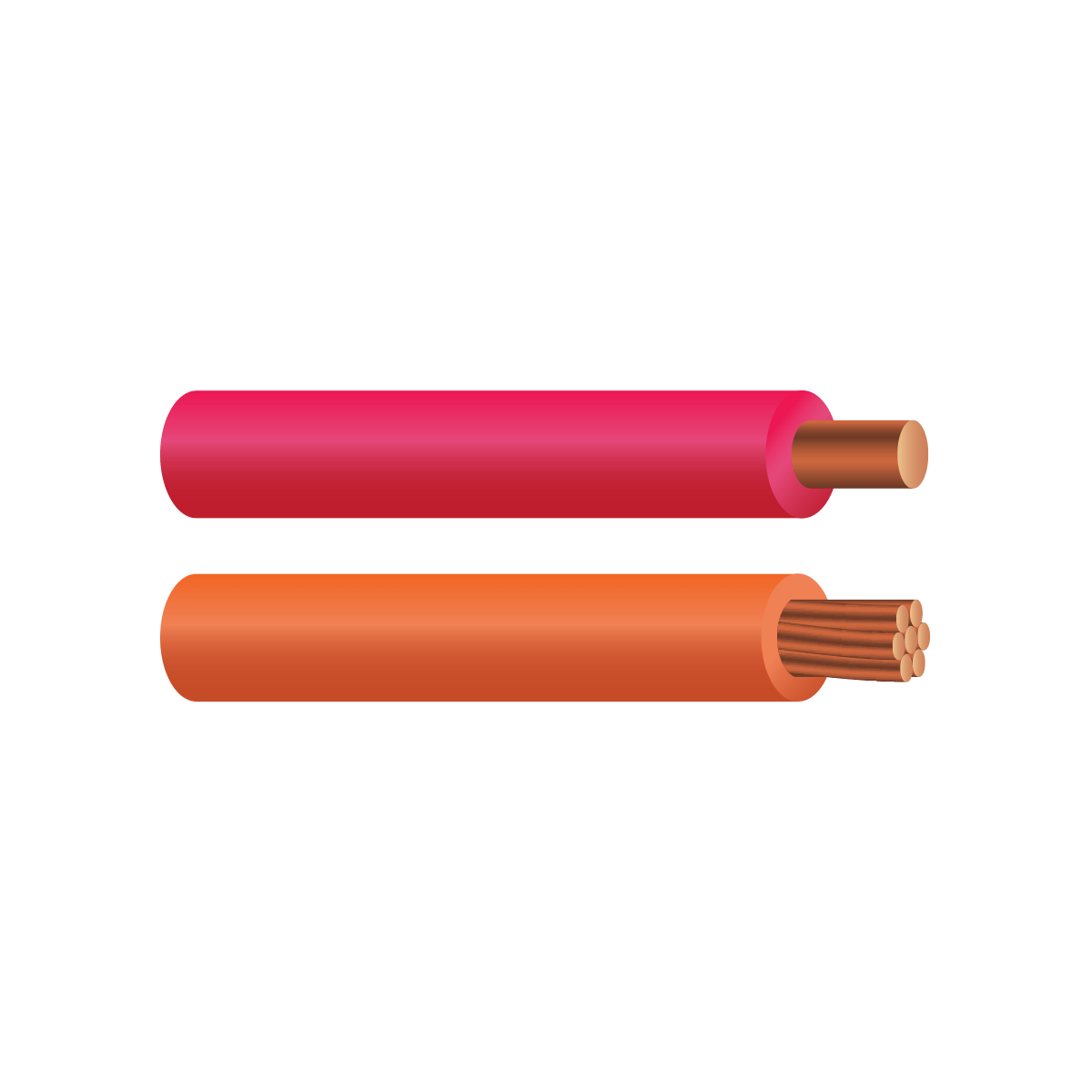

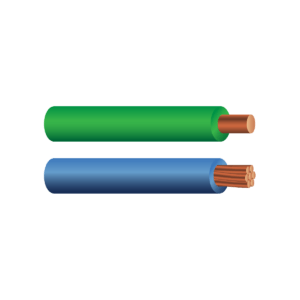

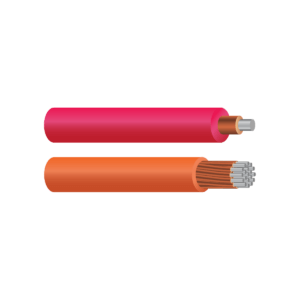

Conductor Core Material:

CopperConductor Core Type:

Solid | StrandedGauge Size:

8 AWG | 10 AWG | 12 AWG | 14 AWGReel Size:

500’ | 1000’ | 2500’ | 5000’Insulation Material:

High-Density High Molecular Weight Polyethylene (HDHMWPE)Color:

-

Insulation Thickness:

30 mil (30v)Environment:

Construction Site, Gas & Liquid Pipeline, Outdoor, Sewer Pipeline, Underground, Utility Conduit System, Water PipelineEnvironmental Protection:

Abrasion Resistant, Chemical Resistant, Crush Resistant, Impact Resistant, Moisture Resistant, Oil ResistantApplication:

LocatingIndustry:

Construction, Sewer Utility, Electric Utility, Oil & Gas Utility, Telecommunications Utility, Water UtilityCompliance:

AIS, APWA Color Code, ASTM Standards, BABA Act, National Electrical Code, RoHS, UL StandardsAssociated Brand:

Pro-Line