More Than Just Stickers: How Quality Control Labels Transform Manufacturing

Quality control labels make a huge difference in manufacturing excellence, but many facilities don’t realize how important they are. Our data shows that the right QC labels can cut product defects by up to 40% and make operations smoother. The key is picking quality control inspection labels that match your specific needs and materials. We’ve seen firsthand how inventory quality control labels keep equipment accurate, meet regulations, and make workflows easier to track.

This piece covers everything you need to know about custom quality control labels – from types to picking the perfect match for your industrial setting. On top of that, it shows how QC quality control labels help trace products and reduce mistakes in busy production environments. You’ll learn to set up a quality control labels template system that fits your operation’s needs. This will boost your manufacturing excellence and help maintain consistent product quality.

Why QC Labels Are Critical for Manufacturing Excellence

Quality control labels do much more than just identify products. These visual indicators are the foundations of efficient manufacturing systems that create real benefits throughout operations. Let’s get into why these labels are crucial to manufacturing excellence.

Maintaining equipment accuracy and safety

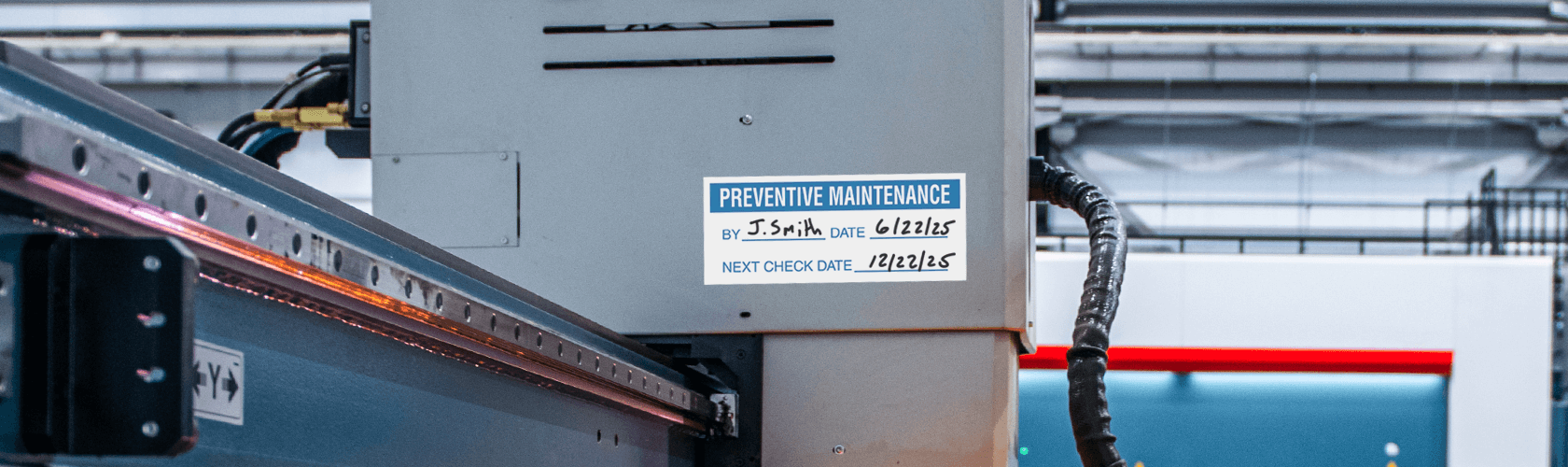

Product quality depends on equipment precision in manufacturing environments. Quality control inspection labels document calibration status and make sure machines work within specified parameters. These labels help spot potential problems before they turn into major failures.

QC labels clearly document regular inspections and create a safer workplace by marking equipment that requires maintenance or poses risks. This systematic approach to equipment monitoring reduces unexpected breakdowns and repairs substantially. You’ll save money by minimizing downtime.

Ensuring compliance with ISO and FDA standards

Manufacturing facilities must follow strict regulatory frameworks, especially in highly regulated industries. QC quality control labels prove compliance with standards like ISO/IEC 17025. This standard ensures competence in calibration and testing laboratories through traceable records and clear identification of calibration statuses.

These labels support FDA and GMP guidelines that just need material traceability and strict quality controls. Manufacturers risk penalties, production shutdowns, or product recalls without proper labeling systems. Quality control labels template systems protect against compliance issues during regulatory audits.

Improving workflow visibility and accountability

Custom quality control labels communicate product or component status instantly across supply chains. Teams can coordinate workflows and manage resources better by quickly recognizing inspection outcomes, calibration status, or rejection reasons.

Inventory quality control labels eliminate confusion on the shop floor. They support inspection procedures and ensure only verified products move forward. These labels become part of standardized processes that boost traceability and accountability across teams when used consistently.

QC labels display critical information like pass/fail results, calibration dates, or rejection reasons prominently. They communicate instantly without requiring workers to check digital records. This saves valuable time in the ever-changing manufacturing world.

Common Types of QC Labels Used in Industry

Manufacturing facilities need different types of quality control labels to maintain standards and track processes. Each label plays a specific role in production and provides visual cues that guide work and document compliance.

Inspection Labels: Accepted, Rejected, Hold

Quality assurance processes on manufacturing floors depend on inspection status labels. These color-coded markers show if items meet production standards at a glance. “Accepted” labels (typically green) show products that passed inspection and can move ahead. “Rejected” labels (often red) mark items that don’t meet requirements and stop defective products. “Hold for Inspection” labels (usually yellow) mark items that need more evaluation.

Clear visual markers reduce confusion on the shop floor, especially when quick decisions affect production efficiency. Regular use of inspection labels creates standardized processes that improve product tracking throughout production.

Calibration Labels with Traceable Records

Accurate instruments need regular calibration checks. Calibration labels record key details such as:

- Date of last calibration

- Due date for next calibration

- Technician identification

- Equipment ID numbers or serial numbers

Many facilities use Trident’s Pocket Pack Cable Label (PPCL) style write-on calibration labels that include a clear self-laminating tail. This tail wraps around instruments and protects written information from damage. The Pocket Pack Self-laminating Cable (PPSC)-style vinyl control labels work well for applications requiring a smaller footprint. These labels have permanent adhesive, and self-laminating polyester covers that protect against grease, oil, and moisture.

Serviced and Tested Labels for Maintenance Logs

Equipment maintenance records help prevent unexpected downtime. Serviced labels show completed maintenance work, while tested labels confirm equipment works properly after service.

LSS-style security seals break when someone tries to remove them. These frangible vinyl seals protect equipment between scheduled maintenance checks. Most service labels have spaces to write technician details, service date, and next service date.

Custom Quality Control Labels for Branding and Tracking

Some operations need flexible labels that match specific tracking requirements. These labels often include:

- Company logos for brand consistency

- Unique identifiers including barcodes or QR codes

- Sequential numbering for batch tracking

- Variable data fields for department-specific information

Custom labels help streamline workflow management by connecting with quality management systems. Barcoded labels support audit preparation and problem tracking. They link physical items to digital data in ISO-compliant settings.

Understanding the Role of QC Labels in Manufacturing

Quality control labels do more than just mark products – they act as silent gatekeepers in manufacturing operations. These labels guide workflow, check compliance, and share significant information without needing extensive documentation checks.

Visual communication for inspection and calibration status

Quality control inspection labels serve as instant visual signals about equipment and product status. Colors and clear typography help workers quickly spot important information on busy production floors. To cite an instance, green “Accepted” labels show items that passed inspection, while red “Rejected” labels stop defective products from moving forward.

Calibration labels show whether measuring instruments meet required standards. Each label displays calibration dates, due dates, and technician details to keep measurements reliable. A quick look at a labeled instrument tells operators what they need to know about its reliability.

Reducing human error in ever-changing environments

Quality control labels help prevent mistakes that can get pricey in manufacturing settings where quick decisions affect product quality. Many facilities faced these problems before they set up proper labeling systems:

- Using uncalibrated measuring equipment

- Releasing non-conforming products

- Processing expired components

Custom quality control labels help alleviate these risks by clearly showing critical information that prevents mistakes. Workers get immediate guidance through visual indicators instead of checking digital records or manuals.

Supporting traceability and audit readiness

Quality control labels for inventory create tracking points throughout production. These tracking tools are a great way to get through regulatory audits where traceability often determines compliance.

Labels with barcodes or QR codes merge with quality management systems to improve digital tracking. Physical labels connected to digital records create detailed audit trails that help with internal quality checks and external compliance.

Quality control label templates make documentation practices standard across departments. This approach makes audit preparation easier and confirms quality processes throughout manufacturing operations.

Types of Quality Control Labels and Their Functions

Quality control systems work best with specialized labels that serve specific functions in manufacturing. The right labels help prevent mistakes from getting pricey and create clear documentation throughout production.

Pass/Fail Labels for Inspection Outcomes

Pass/fail labels show product quality status at a glance. These labels make decisions easier with bold text and color-coding – green means “Accepted” and red means “Rejected.” Workers can quickly see if items should move to the next production phase without checking detailed reports. Good pass/fail labels have spaces for the inspector’s name, inspection date, and notes about specific tests.

Calibration Labels with Due Dates and Technician Info

Precision instruments need regular calibration checks that calibration labels track really well. These special tags include spaces for:

- Calibration date

- Next due date

- Technician’s name

- Equipment’s serial numbers

Self-laminating designs keep this vital information safe from damage and readable throughout the calibration period. Many facilities like using PPCLGR-style write-on labels. These labels have clear laminating tails that wrap around instruments to protect against chemicals and moisture.

Quarantine and Rejected Labels for Non-Conforming Items

Products that don’t meet specs get quarantine and rejected labels to stop them from moving through production. These eye-catching markers – usually with bright yellow or red backgrounds – flag items that need more evaluation or rejection. The labels have fields to record specific problems and create trackable records for quality improvements.

Shelf Life Labels for Time-Sensitive Products

Products that can expire need shelf life tracking, especially in food production and pharmaceuticals. These labels show:

- Manufacturing date

- Expiration deadline

- Storage requirements

- Batch identification

This information helps rotate inventory properly and stops expired materials from being used in production.

Custom Quality Control Labels with Barcodes and Logos

Digital systems need custom quality control labels with machine-readable elements. These unique identifiers mix company logos, barcodes, QR codes, and sequential numbers to boost traceability. Physical labels connect to electronic records and create detailed audit trails. This supports internal quality checks and external compliance verification.

Material and Adhesive Considerations for Harsh Environments

The right materials for quality control labels can make or break their performance and lifespan in manufacturing environments. Labels face tough conditions in industrial settings. These conditions can make them hard to read and affect how well they stick if you don’t pick the right materials.

Polyester vs Vinyl: Durability Comparison

The right material choice is vital to keep labels intact in tough manufacturing environments. Polyester labels resist chemicals better and stand up to scratches more effectively. This makes them perfect for long-term use where people handle them often. They cost more upfront but stay readable longer under UV light.

Vinyl labels aren’t quite as tough as polyester but they work great on curved surfaces. You can write on them with pens, pencils, and felt-tip markers. They also hold up well against grease, oil, dirt, and moisture. The Pocket Pack Cable Removeable (PPCR)-style write-on control labels represent this flexibility with their writeable vinyl makeup.

Removable vs Permanent Adhesives

Your adhesive choice needs to match what you’re using it for:

Adhesive Type

Best Applications

Key Characteristics

Permanent

- Long-term compliance labeling

- Strong initial tack, increases bond strength over time

Removable

- Equipment reuse, temporary applications

- Stays in place as needed, peels cleanly without residue

Aggressive

- Textured, oily, or difficult surfaces

- Provides secure bond on challenging surfaces

Removable adhesives are a great way to get through calibration cycles. They stay put while you need them but peel off clean without damaging equipment.

Tamper-Evident Features for Security Compliance

Quality control inspection labels often need tamper-evident features for security. LSS-style security seals use frangible vinyl that tears if someone tries to remove them. These seals let you see right away if someone has messed with the equipment between inspections.

Some labels show “VOID” permanently when someone tries to take them off. This technology helps secure inventory quality control labels. It’s especially useful in regulated industries where proper documentation affects compliance.

Heat and Chemical Resistance Requirements

The environment plays a huge role in how well labels work. Labels that can’t handle heat might fade or lose their stick on warm equipment. You’ll lose important information when this happens. Quality control labels for high-heat areas need materials rated for specific temperature ranges.

Chemicals create their own set of challenges. Self-laminating clear polyester covers help protect against this. PPSC-style circular write-on vinyl control labels show this protection well. They seal written information to keep out grease, oil, dirt, and moisture.

Industry-Specific Applications of QC Labels

Quality control labeling requirements change significantly by industry. Each sector faces unique challenges that need specialized solutions. Manufacturing companies of all sizes adapt their QC labels to specific regulatory frameworks and operational needs.

Inventory Quality Control Labels in Warehousing

Modern warehouses depend on inventory quality control labels to track material flow and keep visibility in storage and distribution. These labels eliminate confusion on warehouse floors by marking items that pass inspection or need more evaluation. Color-coded status indicators help workers quickly identify product conditions and improve picking accuracy. Warehouses handle thousands of SKUs at once, so QC labels with barcoding create vital connections between physical inventory and warehouse management systems.

Healthcare Equipment Calibration and Inspection Labels

Healthcare equipment calibration plays a crucial role in patient safety and treatment outcomes. Medical facilities use specialized QC quality control labels that meet strict ISO/IEC 17025 standards for testing laboratories. The labels feature tamper-evident properties like LSS-style security seals that break when removed. This ensures calibration stays intact between inspections. Medical device calibration labels must resist frequent disinfection protocols with materials that withstand harsh cleaning chemicals and moisture.

Aerospace and Aviation Compliance Labeling

The aerospace industry requires the highest level of documentation precision. Custom quality control labels in this heavily regulated sector must include tamper-proof features and withstand extreme temperatures and pressure changes. Aviation maintenance teams use quality control labels template systems to document every inspection and part replacement under strict FAA guidelines. These labels create continuous documentation chains that support airworthiness certification.

Food and Beverage Shelf Life Tracking

Food producers use quality control inspection labels to monitor shelf-life information and processing parameters. The materials must stick to different packaging surfaces and resist cold storage conditions. The labels track expiration dates and batch numbers, which allows precise recalls if safety issues occur.

How to Choose the Right QC Label for Your Operation

Quality control labels need careful selection based on how you plan to use them and where they’ll end up. A one-size-fits-all approach rarely works. The right QC labeling comes from smart choices that match your specific needs and conditions.

Label Size and Visibility Requirements

The dimensions you pick for quality control inspection labels can make or break their usefulness. Your labels should fit all the details you just need – from calibration dates to technician initials and equipment IDs. They must be readable quickly while having enough room for all information. Color-coded backgrounds and bold text help people spot critical labels fast in busy work areas. The equipment size plays a key role too – smaller devices work better with compact labels that stay out of the way.

Print Method Compatibility: Handwritten vs Pre-Printed

QC labels come as pre-printed options or write-on versions – each works best for different situations. Pre-printed labels look professional and consistent but don’t adapt well to changing information. Write-on labels like PPCR-style vinyl markers work with pens, pencils, and felt-tip markers. Your label surface must match your documentation style. Thermal transfer printing works differently than handwritten notes and needs specific materials.

Matching Label Type to Equipment Surface

The surface type determines how well labels stick. Rough or oily surfaces need strong adhesives that last throughout use. Standard permanent adhesives work fine on smooth surfaces. Equipment that needs frequent maintenance does better with removable labels that peel off clean. PPCLGR-style labels with clear self-laminating tails are a great way to protect written information on curved surfaces like tubes or handles.

Using a Quality Control Labels Template for Standardization

Template systems create uniform labeling across departments and help teams avoid costly mistakes. These templates ensure every label contains the required information, which makes training easier and simplifies the whole process. Well-laid-out labeling systems support lean processes, maintenance programs, and quality standard compliance. Your continuous improvement plan should include regular template updates and reviews.

Conclusion

This piece has shown how quality control labels are vital components in manufacturing excellence. Without doubt, these simple tools deliver powerful results when used strategically. Quality control inspection labels cut defects by up to 40% and create visual communication systems that prevent errors from getting pricey. On top of that, they provide compliance documentation that protects operations during regulatory audits.

Picking the right labels starts with knowing your operation’s specific requirements. Surface types, environmental conditions, and information needs should guide your choices. Each decision affects your label’s effectiveness and longevity – from tamper-evident features for security compliance to self-laminating materials for harsh environments.

Quality control labels can work well for challenges unique to different industries. Healthcare facilities, to name just one example, just need specialized solutions that can handle disinfection protocols. Aerospace applications need labels that work reliably in extreme conditions. Whatever your industry, standardized quality control labels template systems create consistency that improves communication between departments.

Your QC labeling programs should balance immediate visibility with durability needs. Investing in the right materials—polyester for chemical resistance or vinyl for flexibility—pays off through fewer errors and better operational efficiency. Looking at quality control labels as strategic tools rather than mere stickers shows a fundamental change toward manufacturing excellence.

Note that quality control labels are the foundations of your quality management system. These visual indicators communicate instantly, prevent costly mistakes, and document compliance efforts. Your manufacturing operation can achieve better precision, reliability, and consistency by applying the strategies outlined here – true hallmarks of manufacturing excellence.